HTML

-

This paper discusses the issues surrounding the introduction, acceptance and production of nucleopolyhedrovirus, specifically Helicoverpa NPV (HNPV), in Australia.

HNPV has faced a number of significant barriers to introduction. These barriers include:

• Regulatory

• Grower perception

• Competition with low cost synthetic insecticides

• In-vivo production problems-high labour require ment (high cost of labour), volume of production and product quality.

Conversely there have been a number of issues which have effectively opened the doors of opportunity to products like HNPV:

• Increased frequency of resistance to synthetic insecticides

• Community pressure to reduce usage of toxic chemicals

• Need for farming practices to be more sustainable.

The virus has now become an established part of many IPM programmes in Australian agriculture and horticulture. An additional difficulty for biopesticides like this is that unless local strains can be found it is virtually impossible to import strains from other countries because of the strict import regulations in Australia

-

The Australian regulatory system is geared towards the administration and registration of synthetic insecticides. The majority of insecticides registered are owned by large multinational companies who have access to data generated across the world. Small companies wanting to introduce environmentally friendly products such baculoviruses for use as insecticides are subjected to exactly the same requirements as a company applying to register a synthetic compound. Along with this comes the expectation that the company applying for registration of the product has extensive data. Without this data registration can be very difficult, if not impossible.

Additionally it is extremely cost restrictive to import "live" organisms into Australia because of quarantine requirements. Any foreign organisms need to be screened against a large range of non-target species which is very costly and time consuming.

-

The first nucleopolyhedrovirus to be introduced to the Australian market was a product called Elcar. It was an Heliocoverpa NPV produced by in-vivo methods in Helicoverpa zea in the USA. Shell Chemical Company introduced the product into the Australian market in the 1970's at a time when import restrictions were less stringent than today. The arrival of Elcar coincided with that of the synthetic pyrethroids. The NPV could not match the speed and effectiveness of the SP's. This meant the product did not achieve sufficient market share to warrant continued support of the registration by the manufacturer.

The high relatively costs of production of NPV's means they are not always able to compete with synthetic chemistry in the market. This along with the perceived poor performance of NPV's versus the synthetic compounds continues to be a barrier to market acceptance of this technology.

-

Despite being innovative Australian growers are always very aware of their input costs as they operate in an environment of low margins and no subsidies. For these reasons they view biopesticides with some scepticism until the products have proven themselves. At the outset growers saw HNPV as being a product which was not able to match it with cheap effective products such the synthetic pyrethroids-Elcar in the 1970's. This perception was carried over to the later re-introduction of the virus.

Extensive research and extension work by researchers such as Dr David Murray and Dr Caroline Hauxwell (both of QDPI & F) have served to provide a better understanding of the use of baculoviruses resulting in improved field performance. This along with improved quality of the commercially available products has meant greater acceptance of the technology.

-

In-vivo production of baculoviruses has associated with it a number of significant issues:

• Unreliability of supply due to the fickle nature of insect colonies. Production is totally dependent on the size and health of the insect colony..

• High production costs due to the high labour requirement. Standard methods of in-vivo production are extremely labour intensive meaning costs can be prohibitive in a country such as Australia

• Poor quality virus. Virus quality can be affected by a number of things including quality of inoculum, cleanliness and health of culture conditions, temperature of incubation, length of incubation, harvesting methods and storage conditions after harvest.

Regulatory

Competition with low cost synthetic insecticides

Grower perception

In-vivo production problems

-

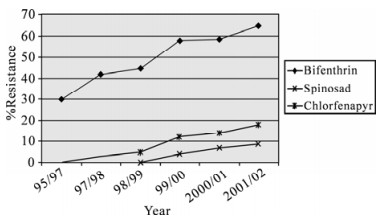

The repeated use of synthetic insecticides has resulted in rapid increase in the frequency of resistance to those insecticides (see Fig. 1). An insect in Australia which has a history of very rapid development of resistance to synthetic insecticides, is Helicoverpa armigera. The industry has put in place resistance management strategies to try and stave off resistance with some limited success. The advent of HNPV for use against H. armigera has meant an additional tool in the fight against resistance. To date no resistance has been detected to HNPV in Australia and this is despite extensive usage in intensive cropping areas such sorghum and cotton.

-

In many intensive agricultural growing regions communities are becoming aware of the potential problems associated with the use of chemicals in agriculture. Whether these concerns are based on fact or not is not always considered important. What is important is that the communities would like to see chemical usage decreased. This becomes a significant opportunity for baculoviruses. However in order to gain acceptance the communities need to be educated on the safety of the baculoviruses.

-

In the past 15 years agricultural researchers, agronomists and growers have been working towards sustainable agricultural systems in Australia. Environmental issues as well the rapid development of resistance to synthetic insecticides has led researchers to search for integrated pest management systems. The downfall of any IPM system is the use of a disruptive insecticide. Products which are target specific such as HNPV are not disruptive and mean that ecological balances can be maintained and IPM becomes a more realistic achievement.

HNPV has become an established component of many IPM programmes especially where Helicoverpa is a major pest such as: sorghum, sweet corn, lettuce and tomatoes. However it does also fit well where Helicoverpa is a less significant pest. For example in strawberries where predatory mites (Phytoseiulus persimilis) are used to manage two spotted mite (Tetranychus urticae), low level Helicoverpa infestations are effectively managed with HNPV without disruption to the predatory mites.

Increased frequency of resistance to synthetic insecticides

Community pressure to reduce usage of toxic chemicals.

Working towards sustainable farming systems

-

One of the main threats to baculoviruses in Australia, and probably world wide, is the increasing uptake of genetically modified crops which are resistant to insect attack. GM cotton in Australia has drastically reduced usage of the majority of foliar applied insecticides including biologicals such as NPV's in this crop.

The only option for increased growth of usage of HNPV in Australia is to expand the use into other crops such vegetables and fruit where GM crops are probably some way off. This is a strategy also being adopted by many of the manufacturers of synthetic insecticides.

-

In 2000 Ag Biotech Australia (previously known as Australian Produced Biologicals) established a pilot plant to produce Helicoverpa nucleopolyhedrovirus using in-vivo methods. This product was produced in Helicoverpa armigera using the American isolate from H. zea and was branded ViVUS. The first commercial sales of ViVUS were made in 2003.

Initial production was based on a single colony of H. armigera. Colony management was based on tried and tested systems being used in many insectaries around the world. All processes were manual with live larvae being placed onto diet using paint brushes. This system was costly, largely due to the high labour component, and hence not sustainable in Australia's competitive market place.

-

The first improvement was to establish a second insect colony in a totally separate part of the country. This provided Ag Biotech with much improved security of production.

A visit to the USDA in Mississippi supplied some useful suggestions on improved insect handling. The automation of the processes was undertaken by inhouse engineers. Many prototypes later the company now has an insect handling system which is highly automated, minimises physical contact with the insects and utilises all growth stages to their maximum. Eggs are place individually onto diet which means fewer eggs need to be produced which has obvious flow on effects for colony size requirement.

-

Streamlining the actual production of the virus proved to be slightly more difficult as there was very little information publicly available on how to cost effectively produce commercial quantities of a good quality virus.

Yes, it is true that the following basic rules regarding production of quality NPV was readily available in numerous references:

• Colony health

• Maintenance of near sterile culture conditions even after infection

• Inoculum quality

• Infection dose and timing

• Incubation temperatures after infection and once virus has commenced multiplication

• Timing of harvest

• Speed and cleanliness of harvesting system.

However when trying to scale up to produce commercial volumes it soon became apparent that these basic guidelines were not necessarily easy to achieve and maintain especially when trying to automate the processes.

The one aspect which caused the most heartache was that of virus extraction and formulation. Logically it is a simple process of filtration, virus identification, polyhedral inclusion body (PIB) counting and finally dilution. However separating the virus from the complex mixture of insect bodies, frass and diet remains, without losing too many of the PIBs proved to be a complex task. It required significant adaptation of a commercially available filtration system to solve the problem.

The ViVUS story - (Ag Biotech Australia - from small beginnings)

The insect colony

Virus production

-

The next phase of the development of this Australian made virus was to replace the American virus strain with a native Australian strain. A native strain had been isolated many years previously by R.E.Teakle, a researcher from the Queensland Department of Primary Industries and Fisheries. An agreement was struck between Ag Biotech and QDPI & F to get access to the strain for commercial production.

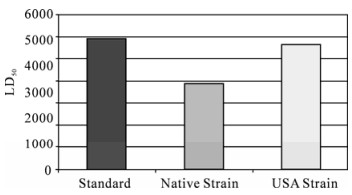

In laboratory potency testing the native strain proved to be significantly more potent than the American strain as can be seen from the sample data represented in the Fig. 2.

Figure 2. Comparison of LD50 between NPV standard, a strain from the USA and a native Australian strain.

The lower LD50, increased potency, led to field trial testing which again confirmed the effectiveness of the native strain. The data in Table 1 represent a small proportion of the field data generated with the native strain, ViVUS Gold.

Table 1. Effectiveness of ViVUS GOLD and ViVUS on Helicoverpa armigera in tomatoes

ViVUS Gold was first registered in 2004 with a list of uses on the label similar to the previously registered ViVUS. Subsequent research has led to a vastly increased list of uses as can be seen in Table 2. The application of ViVUS Gold can now also be done through the irrigation water a method which has proven to be very successful by a number of innovative growers.

Table 2. List of crops and uses appearing on the ViVUS Gold label

Ag Biotech has developed a process by which a more concentrated form of the virus can be produced. The end product will contain 5×109 PIBs per mL instead of the current 2×109. The end product will be packed into smaller containers than currently (current pack size is 10L with the new pack being 5L). From the users point of view this will mean less waste packaging to dispose of Refrigerated storage and transport will also become less of a problem with smaller pack sizes-more product in a smaller space.

-

The introduction of Helicoverpa nucleopolyhedrovirus has been successfully introduced into the Australian agricultural and horticultural market. This has taken significant research and investment from private and government sources. The product has potential to grow but requires continued education of growers and the community of its advantages. Ongoing research and product improvements will see biopsticides like ViVUS become well established in manycrops.

DownLoad:

DownLoad: